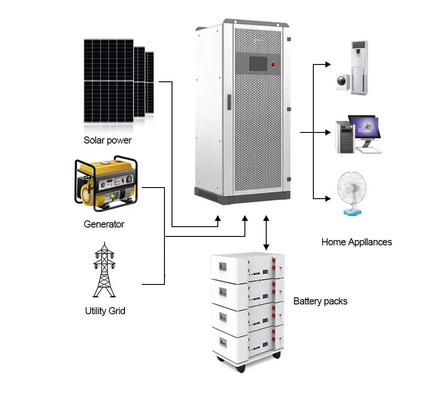

100kW 240V High-Leg Delta Hybrid Inverter - Industrial Microgrid Power Solution

Industrial-Grade Power Conversion System

This advanced 100kW hybrid inverter delivers reliable three-phase and split-phase power for large-scale industrial and commercial applications. Featuring a unique 240V high-leg delta configuration with split-phase output, it provides unparalleled flexibility for facilities requiring both three-phase motor drives and 120/240V single-phase loads. With up to four MPPT trackers supporting 240kW PV input and 420-850V battery compatibility, this system represents the cutting edge of industrial power conversion technology.

Key Differentiators from Lower Capacity Models:

-

Enhanced Power Capacity: 100kW continuous (110kVA peak) output for heavy industrial equipment

-

Expanded Solar Input: Up to four independent MPPT channels for complex solar arrays

-

Higher Voltage Battery Support: 420-850V range for modern high-voltage storage systems

-

Advanced Grid Interaction: <20ms transition time between grid-tie and island modes

Technical Specifications

| Category |

Specification |

Technical Notes |

| AC Output |

240V High-Leg Delta + Split Phase |

Provides true three-phase 240V (L1-L2-L3) while deriving 120V (L2-N) |

| Continuous Power |

100kW (110kVA peak) |

110% continuous overload capacity |

| PV Input |

120/180/240kW |

Quad MPPT with 99.9% tracking efficiency |

| Battery Voltage |

420-850VDC |

Supports all major lithium chemistries |

| Dimensions |

1200×800×2050mm |

Forklift pockets for easy installation |

Advanced Technical Features

1. Precision Voltage Conversion

The inverter's patented phase-shifting technology generates clean three-phase 240V power while simultaneously providing 120V single-phase output. This unique capability:

-

Eliminates the need for external transformers

-

Maintains perfect phase balance (±1%)

-

Provides <3% THDi for sensitive equipment

-

Features <20ms transition time between operation modes

*Technical Insight: Utilizes DSP-controlled IGBT modules with 16kHz switching frequency for precise voltage regulation and rapid response to load changes.*

2. Intelligent Solar Harvesting

Our advanced MPPT system ensures maximum energy harvest:

-

Up to four independent tracking channels

-

250-850V operating range

-

1,000V maximum input voltage

-

Cold start capability down to 150V

-

99.9% peak tracking efficiency

Performance Data: Achieves 98.5% conversion efficiency at nominal load with <0.5s MPPT response time to changing irradiance conditions.

3. Industrial Battery Management

The advanced battery interface supports:

-

Multiple lithium chemistries (NMC, LFP)

-

Configurable charge profiles

-

Temperature-compensated charging

-

120/180/240kW charging power

-

State-of-health monitoring

*Safety Feature: Includes integrated DC arc fault detection, ground fault protection, and rapid shutdown capability compliant with NEC 2017/2020.*

Target Applications

Industrial Manufacturing

-

Automotive assembly plants

-

Steel production facilities

-

Heavy machinery operations

-

Industrial process lines

*Case Study: A Midwest manufacturing plant reduced energy costs by 42% after installing this system to power their 24/7 production line while maintaining power quality for sensitive CNC equipment.*

Commercial and Institutional

-

Large retail complexes

-

Hospital campuses

-

University facilities

-

Data centers

Technical Advantage: Parallel operation allows seamless capacity expansion as energy needs grow, with <5ms synchronization between units.

Utility and Energy Infrastructure

-

Microgrid primary power sources

-

Peak shaving applications

-

Renewable integration systems

-

Remote community power

Feature Highlight: Supports advanced grid services including frequency regulation and voltage support with <100ms response time.

System Architecture

Power Conversion

-

Three-level ANPC topology

-

98% peak efficiency

-

<20ms transfer time

-

100% unbalanced load capability

-

200% short-term overload capacity

Control System

-

Dual-core DSP processor with FPGA co-processing

-

Real-time load monitoring and forecasting

-

Predictive maintenance alerts

-

Remote firmware updates

-

Cybersecurity protection

Protection Features

-

Comprehensive overvoltage/undervoltage protection

-

Overfrequency/underfrequency protection

-

Reverse polarity protection

-

Short circuit protection

-

Ground fault monitoring

-

Arc fault detection

Installation Requirements

Electrical

-

400A minimum circuit breaker

-

2/0 AWG copper conductors minimum

-

Proper grounding system (<0.1Ω to earth)

-

Surge protection devices (40kA minimum)

Environmental

-

800mm clearance for ventilation

-

Ambient temperature monitoring

-

Dust filters in high-particulate areas

-

Elevated mounting in flood zones

-

Corrosion protection for coastal installations

Certification & Compliance

This industrial-grade inverter meets or exceeds:

-

UL 1741 SB (Safety)

-

IEEE 1547-2018 (Grid Interconnection)

-

FCC Part 15 Subpart B (EMC)

-

CEI 0-21 (Italian Grid Code)

-

NEC 2020 Rapid Shutdown

-

IEC 62109-1/-2

Note: Certification markings are visible on product label. Always verify current certifications with manufacturer before installation.

Frequently Asked Questions

Performance

Q: What's the efficiency curve across different load levels?

A: Maintains >96% efficiency from 30-100% load thanks to advanced multi-level conversion topology.

Q: How does it handle large motor starting currents?

A: 200% overload capability for 10 seconds handles most industrial motor starts.

Compatibility

Q: What battery management systems are supported?

A: Native support for Tesla, BYD, LG Chem, CATL, Pylontech through CAN/RS485.

Q: Can it work with flow batteries?

A: Yes, with configurable charge profiles for vanadium redox and other flow chemistries.

Installation

Q: What's the recommended maintenance schedule?

A: Semi-annual inspection including thermal imaging, firmware updates, and air filter cleaning.

Q: How many units can operate in parallel?

A: Supports up to 16 units in parallel for 1.6MW systems with centralized control.

Why Choose This Inverter?

-

Industrial Reliability: Military-grade components rated for 100,000+ hours MTBF

-

Future-Proof Design: Software-upgradable for new features and protocols

-

Energy Optimization: Advanced forecasting algorithms maximize self-consumption

-

Reduced Downtime: Hot-swappable components and predictive maintenance

-

Smart Monitoring: Cloud-connected with real-time analytics and alerts

-

Global Compliance: Meets international standards for worldwide deployment

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!