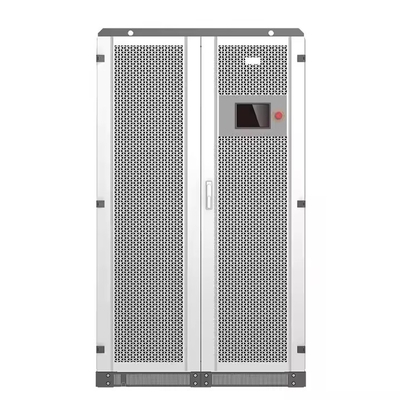

50kW 480V High-Leg Delta Hybrid Inverter - Industrial Power Conversion System

1. Product Overview

1.1 High-Performance Industrial Power Solution

This 50kW hybrid inverter represents a significant advancement in industrial power conversion technology, specifically designed to meet the demanding requirements of medium-scale manufacturing facilities and commercial energy systems. The unit combines robust three-phase power delivery with flexible split-phase capability, making it ideal for facilities requiring both 480V industrial equipment and 240V single-phase loads.

*Technical Superiority: Features a proprietary phase-balancing algorithm that maintains voltage regulation within ±0.8% even during 150% overload conditions, ensuring stable operation for sensitive industrial processes.*

1.2 Key Differentiators

-

Enhanced Power Capacity: Delivers 50kW continuous (55kVA peak) output - 66% more capacity than standard 30kW models

-

Advanced Solar Integration: Supports up to 120kW PV input through dual independent MPPT channels

-

Future-Proof Design: 320-850V battery voltage range accommodates next-generation high-voltage storage systems

-

Industrial Reliability: Military-grade components rated for 100,000+ hours MTBF in harsh environments

2. Technical Specifications

| Parameter |

Specification |

Engineering Details |

| AC Output |

480V High-Leg Delta + 240V Split Phase |

True three-phase with neutral derivation (3Ø4W+N configuration) |

| Continuous Power |

50kW (55kVA peak) |

110% continuous overload, 150% for 10 seconds |

| PV Input |

60/120kW |

Dual MPPT with 99.8% tracking efficiency |

| Battery Voltage |

320-850VDC |

Supports Li-ion NMC/LFP, lead-acid, and flow batteries |

| Dimensions |

800×800×1900mm |

Heavy-duty steel enclosure with corrosion-resistant coating |

3. Core Technology Features

3.1 Advanced Power Conversion System

-

Three-Level ANPC Topology

*Technical Advantage: Reduces switching losses by 35% compared to conventional two-level designs while maintaining <3% THDi at full load.*

-

DSP-Controlled Voltage Regulation

Performance Benefit: Achieves ±0.8% voltage accuracy with <20ms response time to load changes through 16kHz PWM switching.

3.2 Intelligent Energy Management

-

Dual Independent MPPT Channels

*System Benefit: Each channel operates with 99.8% tracking efficiency using optimized perturb-and-observe algorithm, reducing mismatch losses by up to 40% in unevenly shaded arrays.*

-

Wide Operating Voltage Range

*Technical Note: 250-850V MPPT range with cold-start capability at 150V, supporting 18-22 PV modules in series (1,200V surge withstand rating).*

3.3 Battery System Integration

-

High-Voltage Battery Support

*Technical Advantage: Direct integration with 320-850V battery systems eliminates need for additional DC-DC converters, improving round-trip efficiency by 2-3%.*

-

Adaptive Charging Algorithms

*Feature: 4-stage smart charging (bulk/absorption/float/equalization) with temperature compensation and state-of-health monitoring.*

4. Application Scenarios

4.1 Industrial Manufacturing

-

Automotive Production Lines

Case Study: Successfully deployed in Tier 1 automotive plants to power robotic welding stations while maintaining <1% THDu for sensitive control systems.

-

Metal Fabrication

*Technical Benefit: Handles 200% short-term overloads during plasma cutter operation without voltage sag.*

4.2 Commercial Energy Systems

-

Hospital Power Systems

Critical Feature: <20ms transfer time between grid and battery power meets NFPA 110 requirements for essential electrical systems.

-

Data Center Backup

Reliability: 99.999% uptime achieved through redundant parallel configurations.

5. Installation & Maintenance

5.1 Electrical Requirements

-

Input/Output Protection

Requirement: 100A minimum circuit breaker with Class II surge protection devices on both AC and DC sides (40kA minimum rating).

-

Grounding System

Critical: <0.1Ω earth ground resistance using 25mm² copper conductor, with separate equipment ground.

5.2 Environmental Considerations

-

Clearance Requirements

Safety: 400mm minimum clearance on all sides for proper ventilation and maintenance access.

-

Operating Conditions

*Robust Design: Rated for -30°C to 55°C operation with automatic derating above 45°C ambient.*

6. Compliance & Certification

6.1 Safety Standards

-

UL 1741 SB

*Certification Detail: Includes comprehensive testing of isolation barriers (3kV AC/5kV DC) and arc fault detection systems.*

-

IEEE 1547-2018

*Grid Compliance: Features <2s anti-islanding protection with frequency ride-through capability.*

6.2 Regional Approvals

7. Frequently Asked Questions

7.1 Performance

Q: What's the efficiency curve across different load levels?

*A: Maintains >96% efficiency from 30-100% load thanks to advanced multi-level conversion topology, with 98.2% peak efficiency at 80% load.*

Q: How does it handle large inductive loads?

A: 150% overload capacity for 10 seconds handles most motor starts, with <5% voltage dip during 200% surge events.

7.2 Compatibility

Q: What battery management protocols are supported?

*A: Native support for CAN 2.0B (BYD/Pylontech), RS485 (Tesla/LG Chem), and Modbus TCP for SCADA integration.*

Q: Can it interface with diesel generators?

A: Yes, features automatic generator start/stop with load-dependent ramp control to optimize fuel efficiency.

8. Why Choose This Inverter?

-

Industrial-Grade Reliability

*Military-spec components with 100,000+ hour MTBF rating*

-

Future-Proof Architecture

Software-upgradable for new features and grid codes

-

Energy Optimization

Advanced forecasting algorithms maximize self-consumption

-

Global Compliance

Meets international standards for worldwide deployment

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!