Modular BIPV Mounting System – 115mm Steel Bracket for Rooftop Solar Structures

Introduction

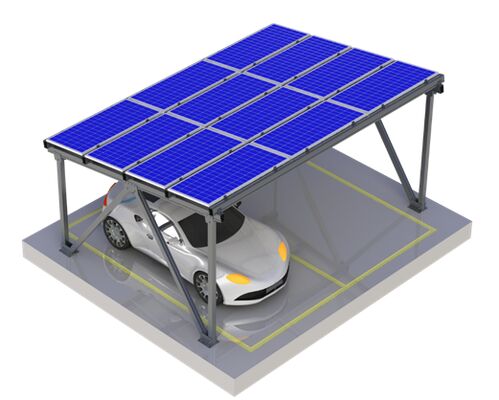

Our Modular BIPV Mounting System is a high-strength, rapidly deployable steel support structure designed specifically for rooftop photovoltaic installations. Utilizing a prefabricated, building-block design philosophy, the system achieves complete assembly through bolted connections, eliminating the need for on-site welding. This significantly enhances installation efficiency, structural safety, and consistency. It is ideally suited for a variety of applications including commercial & industrial rooftop sheds, solar carports, sunrooms, and more.

Key Features & Benefits

-

Fully Modular Design: Composed of standardized columns, beams, purlins, and bracing components, allowing for flexible configuration and rapid on-site assembly.

-

High-Strength Cold-Formed Steel: Utilizes 115mm U-channel and C-section steel, offering excellent load-bearing capacity while minimizing material weight.

-

Superior Corrosion Protection: Features Zinc-Aluminum-Magnesium (ZAM) coating, providing up to 30 years of corrosion resistance—6 to 15 times better than standard galvanized steel.

-

Integrated Water Management: Includes built-in gutters, water guide strips, and drainage systems, ensuring a weatherproof structure without additional sealing work.

-

Welding-Free Assembly: All connections are made with high-tensile bolts (M10, M12 series), enabling tool-based installation, reducing labor skill requirements, and enhancing construction safety.

-

Wind & Snow Load Optimized: Engineered with bracing systems (cross-braces, knee-braces, tie-beams) to withstand demanding environmental loads.

-

Prefabrication Flexibility: Offers both fully prefabricated columns (custom-cut and drilled) and semi-prefabricated options for on-site adjustment, accommodating various roof conditions and height requirements.

Technology & Design Principles

The system employs a bolt-connected space frame structure, where main beams, columns, and purlins form a rigid yet adjustable grid. Key joints—such as column-to-base, beam-to-column, and purlin-to-beam—use pre-punched holes and specialized connectors (cleats, brackets, splice plates) to ensure precise alignment and structural integrity. The design allows for on-site adjustability: purlin cleats feature slotted holes for drainage pitch control, and bracing members can be field-cut from standard 6-meter sections (U4121/U4141) to fit exact dimensions, minimizing waste.

Installation Process Overview

-

Layout & Base Installation: Set out column grid, install anchor bolts (M12 chemical anchors), and secure adjustable column bases.

-

Frame Assembly: Erect columns and main beams using M10x25/M10x140 bolts. Install transverse bracing and tie-beams to stabilize the frame.

-

Purlin & Secondary Structure: Attach purlin cleats to beams, then install purlins. Add longitudinal bracing (knee-braces, struts) as per design.

-

Waterproofing & Accessories: Install gutters (center/edge), downspouts, water guide strips, and maintenance walkways.

-

PV Module Mounting: Secure aluminum or ZAM clamping plates and PV module clamps to purlins using M10x25 bolts.

-

Final Tightening: Once all components and PV modules are positioned, final-torque all bolts to specified values to achieve full structural stiffness.

Application Scenarios

-

Commercial & Industrial Rooftop Sheds: Creates a raised, shaded space over existing roofs, providing roof protection, thermal insulation, and additional usable area.

-

Solar Carports: Modular spans accommodate 1-3 parking bays (6-9m driveways), ideal for parking lots, EV charging stations, and commercial facilities.

-

Residential Sunrooms (BIPV Sunroom): Can be configured as single or double-slope structures for patios, terraces, or balcony enclosures.

-

Agricultural & Logistics Shelters: Cost-effective, quickly deployable coverage for storage, packing areas, or livestock shelter.

Why Choose Our System?

-

Faster Project Completion: Pre-drilled components and bolt-on assembly reduce installation time by up to 60% compared to traditional welded structures.

-

Cost-Effective Material Use: Optimized cold-formed steel sections and efficient cutting plans lower material costs by approximately 15-20%.

-

Design Flexibility & Compatibility: Adaptable to various roof shapes, slopes, and module types. Compatible with most bifacial and monofacial PV panels.

-

Low Maintenance & Long Lifespan: The ZAM coating and robust mechanical connections ensure decades of reliable performance with minimal upkeep.

-

Safe & Scalable Installation: No hot work permits required. The system is easily expandable or reconfigurable for future project modifications.

Frequently Asked Questions (FAQ)

-

Q: What is the typical installation time for a 100kW rooftop shed?

A: With a crew of 4-5, the structural assembly can be completed in 3-5 days, depending on roof complexity.

-

Q: Can the system be installed on uneven roofs?

A: Yes. Adjustable column bases and the option for on-site column cutting (semi-prefab) allow for height compensation of up to 200mm.

-

Q: What wind speed rating does it have?

A: The system is engineered to withstand wind loads up to 150 km/h (approx. 42 m/s) when properly anchored, conforming to international building codes.

-

Q: Is special equipment needed for installation?

A: Standard electric tools (drills, impact wrenches, socket sets) are sufficient. A punching gun and hole cutter are recommended for efficiency.

-

Q: How are water leaks prevented at joints?

A: The system uses overlapping gutter design, sealed end caps, and water guide strips that channel moisture into the main drainage system. Sealant is applied at critical external joints.

Important Notes

-

Always follow the official installation manual and approved structural drawings for your specific project.

-

Ensure all anchor points are installed into sound structural substrate (concrete or structural steel). Verify load capacity of the host roof.

-

Do not cut or modify continuous purlins or main beams without engineering approval.

-

Final torque tightening of all bolts must be performed after PV modules are placed to allow for minor alignment adjustments.

-

Regular inspection of bolts and corrosion protection is recommended every 2-3 years in harsh environments.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!